Engine mounts play a crucial role in stabilizing your vehicle’s engine and reducing vibrations. Over time, these mounts can develop cracks due to wear and tear.

If you’re facing this issue, you might wonder whether welding is a viable repair option. Here’s what you need to know:

Can you weld a cracked engine mount?

You can weld a cracked engine mount if it’s metal, However, rubber or hydraulic mounts cannot be welded, so they must be replaced for a reliable and long-lasting solution.

Table Of Content

- Why Do Engine Mounts Crack?

- Is it worth repairing a cracked engine mount?

- Is It Safe and Practical to Weld a Cracked Engine Mount?

- Can you weld all types of engine mounts?

- Can welding damage the engine or nearby components?

- How to Weld a Cracked Engine Mount.

- How long does a welded engine mount last?

- When to Weld and When to Replace?

- Alternative Solutions to Welding

- How can I prevent engine mounts from cracking in the future?

- Frequently Asked Questions

- Conclusion

Why Do Engine Mounts Crack?

Engine mounts crack because they take a lot of abuse. These mounts hold the engine securely while absorbing vibrations.

Over time, wear and tear break them down. Everyday driving, rough roads, and sudden stops all weaken the material.

Rubber mounts, common in many cars, can degrade over time due to heat exposure and oil leaks. Metal mounts may crack from the constant stress of holding the engine in place.

If you’ve had an accident or driven over bumpy terrain, this stress can increase dramatically, speeding up the wear process.

How can I tell if my engine mount is cracked?

Common signs of a cracked engine mount include excessive engine vibrations, unusual clunking noises, or visible shifting of the engine under the hood. You may also notice the engine leaning to one side.

Is it worth repairing a cracked engine mount?

Yes, if the damage is minor and the mount is made of metal, welding can be a cost-effective and reliable solution. However, if the mount is severely damaged or made from rubber or hydraulic material, replacement is a better long-term option.

Is It Safe and Practical to Weld a Cracked Engine Mount?

When done correctly, welding a cracked engine mount can be both safe and practical. Proper welding provides a solid and lasting solution for metal engine mounts, effectively restoring the mount’s strength and stability.

A skilled welder can ensure the repair holds up under the engine’s stress and vibrations, making it a viable long-term fix.

However, rubber or hydraulic engine mounts cannot be welded and must be replaced. Additionally, improper welding can cause misalignment or weaken the mount, leading to further complications. It’s crucial to have the job done by a professional to ensure safety and durability.

In summary, welding a cracked metal engine mount is a reliable repair when handled properly, but always seek expert advice to ensure the best results.

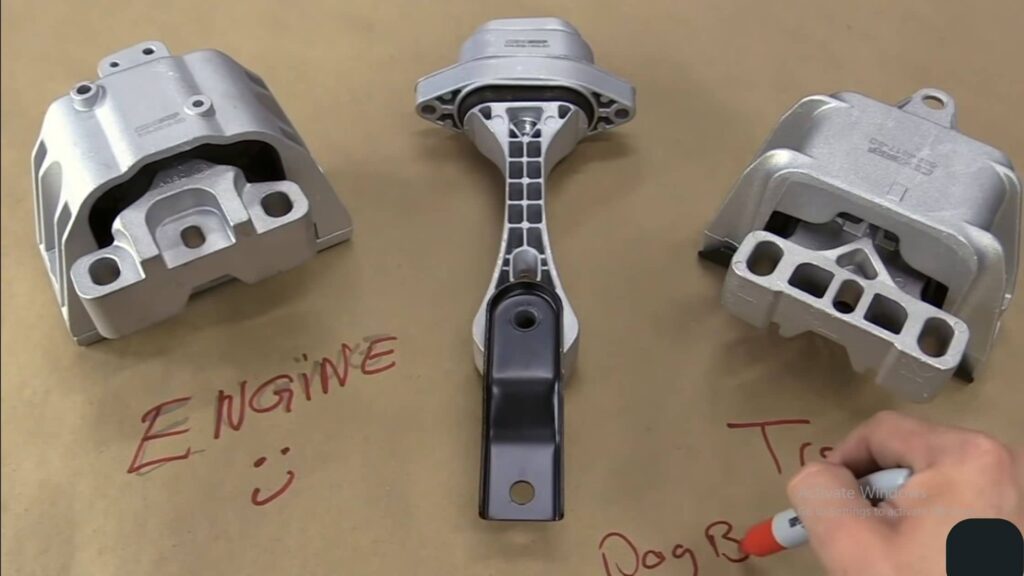

Can you weld all types of engine mounts?

No, not all engine mounts can be welded. Only metal engine mounts are suitable for welding, as they can handle the heat and provide a durable fix.

On the other hand, rubber and hydraulic engine mounts cannot be welded. These materials don’t respond to heat-based repairs and will require a full replacement if they crack or fail.

In short, metal mounts can be welded effectively, while rubber or hydraulic mounts must be replaced.

Can welding damage the engine or nearby components?

Welding near the engine can cause damage if precautions aren’t taken. The high heat from welding can affect electronics, sensors, or wiring in the vicinity. To avoid this, sensitive components should be shielded or disconnected during the repair. Grounding the welding equipment properly also prevents electrical surges.

Having a professional handle on welding ensures that nearby parts stay safe. With the right care, the risk of damage can be significantly reduced, making the process safer for your engine and its components.

How to Weld a Cracked Engine Mount

Follow these steps to ensure a solid repair:

1. Inspect the Crack

Begin by assessing the damage. Ensure the crack is in a metal engine mount, as only metal mounts can be welded. If the damage is too extensive or the mount is severely compromised, replacement can be a better option.

2. Prepare the Mount

Clean the area around the crack by grinding away any rust, dirt, or oil. This creates a clean surface for welding, ensuring a strong bond. If the crack is deep, grind a small “V” groove along it. This allows for better weld penetration and a stronger hold.

3. Choose the Right Welding Technique

For engine mounts, MIG or TIG welding works best, as they offer control and precision. Select the appropriate welding rod or wire based on the type of metal in your mount (typically steel or aluminium).

4. Weld the Crack

Start welding at one end and work steadily along the crack. Make sure to apply a consistent bead and, if necessary, perform multiple passes to fill the groove and ensure a robust repair.

5. Cool and Inspect the Weld

Allow the weld to cool naturally. After cooling, inspect the weld for any gaps or inconsistencies. A solid weld should be smooth and even without noticeable weak spots.

6. Reinstall and Align the Mount

Once the weld is complete, reinstall the engine mount. Double-check that it aligns properly with the engine and ensure all bolts are tightened securely. Misalignment can cause issues later on, so precision is key here.

7. Test the Repair

After reinstallation, start the engine and check for vibrations or unusual noises. A well-executed weld will hold firmly and restore stability to the engine.

Do I need to remove the engine to weld a cracked mount?

Not necessarily. In many cases, a skilled welder can repair the engine mount without removing the engine. However, some mounts are located in hard-to-reach places that may require partial engine lifting or repositioning for access.

How long does a welded engine mount last?

A properly welded engine mount can last for several years, sometimes even as long as a new mount, depending on the quality of the weld and the conditions under which the vehicle operates. If the welding is done by a skilled professional using the right technique, the repair can hold up well under normal driving conditions.

However, factors like driving habits, road conditions, and engine vibrations will affect the lifespan of the weld. Regularly checking the engine mount for signs of wear can help ensure it remains secure over time.

When to Weld and When to Replace?

Knowing whether to weld or replace an engine mount depends on the condition of the mount and the type of material.

When to Weld:

- Metal Engine Mounts: If the mount is made of metal and the crack isn’t too extensive, welding can be a reliable solution. A proper weld can restore the mount’s integrity and durability.

- Cost-Effective Repairs: If you’re looking for a quicker, cost-saving option, welding may be more economical than a full replacement.

When to Replace:

- Rubber or Hydraulic Mounts: These mounts cannot be welded and must be replaced if they are cracked or damaged. The materials are not suitable for heat-based repairs.

- Severe Damage: If the mount is severely cracked, bent, or has multiple fractures, welding may not be enough. In these cases, replacement ensures better performance and safety.

- Old or Worn Mounts: Even if welding is an option, replacing an old or heavily worn engine mount may be the smarter choice to avoid future issues.

In general, metal mounts with minor damage can be welded, while heavily damaged or non-metal mounts should be replaced for long-term reliability.

Alternative Solutions to Welding

If welding isn’t an option or doesn’t seem practical, there are other ways to address a cracked engine mount:

1. Engine Mount Replacement

The most straightforward and reliable solution is to replace the cracked mount entirely. New engine mounts, especially OEM parts, offer a long-term fix and ensure the engine remains securely in place. Though more costly than welding, it’s often the safest option for rubber or hydraulic mounts.

2. Epoxy or Metal Bonding Adhesives

For minor cracks in metal engine mounts, high-strength epoxies or metal bonding adhesives can create a strong bond. However, they may not hold up as well under high stress and are not as durable as welding or replacement.

3. Engine Mount Inserts

Some mounts can be reinforced with aftermarket inserts. These inserts, typically made of polyurethane, provide extra support by reducing movement and strain on the cracked areas. While not a permanent solution for cracks, they can extend the lifespan of a worn mount and reduce vibrations.

4. Mount Rebuild Kits

For certain engine mounts, rebuild kits are available. These kits allow you to restore the functionality of the mount by replacing specific components without having to purchase a brand-new mount. Rebuilding is especially useful for rare or expensive mounts that are hard to find.

5. Custom Fabrication

In some cases, a custom-fabricated engine mount made from durable materials like steel or aluminium can be designed as a replacement. Fabricating a new mount may be an ideal solution if the original mount is no longer available or if a stronger mount is needed for performance applications.

Each alternative comes with its pros and cons, but replacing the mount remains the most reliable choice for long-term peace of mind.

How can I prevent engine mounts from cracking in the future?

Regular inspections, avoiding aggressive driving, and ensuring proper engine alignment can help prevent engine mount cracks.

Also, using high-quality mounts and replacing worn mounts before they fail completely can reduce the risk of cracking.

Frequently Asked Questions:

1) Will a welded engine mount affect the vehicle’s performance?

If the weld is done correctly, a repaired engine mount should restore the engine’s stability without negatively affecting performance. However, a poorly executed weld or a severely damaged mount may cause ongoing issues like vibrations or misalignment.

2) How long does it take to weld an engine mount?

Welding an engine mount usually takes between 1 to 2 hours, depending on the complexity of the crack and the accessibility of the mount. Professional welders might finish the task quicker due to their experience and tools.

3) Can I drive with a cracked engine mount before getting it welded?

Driving with a cracked engine mount isn’t recommended, as it can lead to increased engine vibrations, misalignment, or further damage to the mount and nearby components. It’s best to repair or replace the mount as soon as possible.

4) Can a welded engine mount pass a vehicle inspection?

In most cases, a properly welded engine mount will pass inspection, as long as the repair is solid and safe. However, local regulations vary, so it’s a good idea to consult with your mechanic or inspector before assuming it will pass.

5) What causes excessive vibrations even after welding the mount?

If you still experience excessive vibrations after welding, it could be due to improper engine alignment, other damaged mounts, or issues with related components like transmission mounts or suspension parts. Have a mechanic inspect the vehicle to find the root cause.

6) Can a cracked engine mount cause transmission issues?

Yes, a cracked engine mount can lead to misalignment between the engine and transmission. This misalignment can cause shifting issues, vibrations, or even transmission damage over time if not repaired.

7) What happens if I don’t fix a cracked engine mount?

Ignoring a cracked engine mount can lead to further damage, including excessive engine movement, increased vibrations, damage to nearby components (like exhaust or radiator hoses), and even a failure of the mount, which can be hazardous while driving.

8) Can a cracked engine mount cause engine overheating?

While a cracked engine mount itself won’t directly cause overheating, it can shift the engine, potentially damaging components like the radiator, coolant hoses, or fans, leading to overheating issues. Ensuring the engine is stable is key to avoiding such problems.

Conclusion

Welding a cracked engine mount can be a reliable and cost-effective solution, as long as it’s done correctly and for the right type of mount. While metal mounts are weldable, rubber or hydraulic mounts will require replacement.

It’s crucial to assess the severity of the damage and decide whether welding, replacing, or opting for an alternative repair method is the best route.

If you’re skilled in welding, a DIY repair could work, but for most people, professional help ensures safety and durability. Ultimately, addressing a cracked engine mount promptly will prevent further damage and keep your vehicle running smoothly.